ABOUT NEW WORLD SAFETY

After founding, growing and ultimately selling a successful Health and Safety training organization I could not suppress my burning desire to stay integrated into the protection of human safety and wellness. No doubt my 31 year career as a Toronto Firefighter contributed significantly to that on going “sense of duty”.

When the global pandemic weighed heavy over our world many clients reached out for guidance or in some cases, just to talk. These conversations served to reignite my drive to step back up in support of workplace safety and wellness, both the physical and the mental. In late 2021, I proudly formed New World Safety to act as my vehicle to carry forward that passion. Trust New World Safety to guide, protect and support your organization in an ever evolving and seemingly more complex new world.

Your workplace family are an extension of my own!

About Peter White

- In 1985 Peter started his career with the Toronto Fire Services. Based in downtown Toronto and working out of fire stations 331, 332 and 315, Peter soon amassed a boundless array of first responder experiences transcending every conceivable example of a human emergency. These experiences served to slowly build a vision for expanding his duty to serve beyond the parameters of his first responder role.

- In 1997 Peter formed his first Health and Safety training organization, while maintaining his primary career path if firefighting. Running his first company through the world changing events of 9/11 and the first modern age pandemic (SARS) forced Peter to grow and mature his company at a pace that at times felt torrid. The growth and lessons learned through the process helped Peter build this company into one of respect, dependability and impeccable reputation. In 2015 Peter sold this company to a major community College in hopes that its legacy would continue.

- In 1994 Peter was asked to join the Hazardous Materials response program within Toronto Fire Services. This meant heading back to school and significantly augmenting his existing firefighting certifications. After the events of 9/11 this education took on a completely different dimension with inclusion onto the newly formed Provincial CBRNE team and a stint at the Canadian Counter Terrorism School based in Suffield, Alberta.

- Meanwhile as his first Health and Safety company expanded Peter expanded his trainer/facilitator and coach/mentor offerings in a diverse array of workplace areas: LOTO, Arc Flash/Electrical safety awareness, confined space entry, TDG, WHMIS, emergency response (Fire, Hazmat), bonding and grounding, fall arrest, lab safety, chemical spill, code brown, fire extinguisher, hot work and fire watch, respiratory awareness and fit testing, H2S survive, Hazwoper, emergency incident management, competent supervisor, conflict resolution, ladder safety, customer service for high school students, flammable/combustible liquid safety, E2 preparedness, ammonia emergency response, and so much more.

- “Safety should never be rooted in a simple quest for Due Diligence. Safety must be rooted in moral diligence! “

- Trust New World Safety to guide, protect and support your safety programs in a world that grows more complex every day.

NEW WORLD SAFETY SERVICES

When was the last time you had a trusted partner capable of:

- Custom designing a program and site-specific solutions for your needs

- Maintaining a current knowledge of laws, regulations, codes, standards and industry best practices

- Inspiring your workplace stakeholders with unparalleled energy and entertainment, and motivational enthusiasm in the training room.

Event Keynote Speaker

Peter has amassed a lifetime of first responder and safety related experiences.

- 31 year career as a Toronto Firefighter,

- 20 year career as provincial CBRNE responder

- 27 year career as a top tier training/facilitator/coach/mentor

- Extensive experience as a keynote speaker (Conference of the Americas, multiple safety conferences, speaking engagements)

- Passion, personality, humour and unapparelled communication skills

- Call Peter for your next event

We also provide a FULL Line-Up of Facilitator Services in the following Instructional areas:

Arc Flash Awareness and Electrical Safety

- Air monitoring certification

- Bounding and Grounding

- Basic Health and Safety certification

- CBRNE Preparedness

- Blood Bourne Pathogen Certification

- Code Brown Certification (Chemical Spill for Health Care)

- Compressed Gas Safety

- Chemical Spill

- Confined Space Entry Awareness

- Emergency Response Team Training for Hazardous Materials Response

- Fall Arrest

- Fire Code Audits

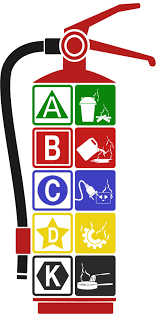

- Fire Extinguisher Training

- Fire Watch Supervision training

WHMIS

- Respiratory Awareness and Fit testing (10 fit testers on staff, 5 Porta Counts)

- H2S Survive Awareness

- Hazwoper (Hazardous Waste Operations and Emergency Response – (OHSA cfr 1910.120)

- Hot Work certification training

- Industrial Fire Brigade Certification (Incipient Stage)

- Emergency Incident Management System Training

- Lab Safety Certification

- Ladder Safety

- Lock out Training meeting CSA Z460

- Pandemic Preparedness Seminars

- Procedure/Guideline Development

- SCBA/APR certification

- Competent Supervisor Certification

- Transportation of Dangerous Goods

- Violence in the Workplace

When a chemical spill occurs the prompt action of trained and competent responders can be critical to the three universal tenets of response: preservation of life, preservation of the environment, preservation of property. Having the correctly matched containment, spill cleanup and PPE supplies can never be overstated. Let NewWorldSafety shepherd your spill cleanup and response program from cradle to grave. Participants will learn about chemical classifications, chemical characteristics, predicting the behaviour of spilled materials, hazard symbols and their meaning, information resources (2020 emergency response guidebook, SDS, Canutec), setting up for entry (Hot Zone), PPE, common spill control and cleanup techniques, air monitoring, cleanup techniques, decontamination concerns, and so much more.

When a chemical spill occurs the prompt action of trained and competent responders can be critical to the three universal tenets of response: preservation of life, preservation of the environment, preservation of property. Having the correctly matched containment, spill cleanup and PPE supplies can never be overstated. Let NewWorldSafety shepherd your spill cleanup and response program from cradle to grave. Participants will learn about chemical classifications, chemical characteristics, predicting the behaviour of spilled materials, hazard symbols and their meaning, information resources (2020 emergency response guidebook, SDS, Canutec), setting up for entry (Hot Zone), PPE, common spill control and cleanup techniques, air monitoring, cleanup techniques, decontamination concerns, and so much more. Any emergency within a healthcare setting can have exponential impacts of Life, Environment and Property. From Medical Daycare intervention medications, Formalin used in Histology Departments, diverse compressed gases used throughout a facility, to the myriad of chemical families found with in labs it is imperative that every hospital have a trained, competent and suitably equipped code brown response team. Let New World Safety be your experienced partner to support the in-house certification of your code brown responders. Participants will learn about chemical classifications, chemical characteristics, predicting the behaviour of spilled materials, hazard symbols and their meaning, information resources (2020 emergency response guidebook, SDS, Canutec), setting up for entry (Hot Zone), PPE, common spill control and cleanup techniques, air monitoring, cleanup techniques, decontamination concerns, and so much more.

Any emergency within a healthcare setting can have exponential impacts of Life, Environment and Property. From Medical Daycare intervention medications, Formalin used in Histology Departments, diverse compressed gases used throughout a facility, to the myriad of chemical families found with in labs it is imperative that every hospital have a trained, competent and suitably equipped code brown response team. Let New World Safety be your experienced partner to support the in-house certification of your code brown responders. Participants will learn about chemical classifications, chemical characteristics, predicting the behaviour of spilled materials, hazard symbols and their meaning, information resources (2020 emergency response guidebook, SDS, Canutec), setting up for entry (Hot Zone), PPE, common spill control and cleanup techniques, air monitoring, cleanup techniques, decontamination concerns, and so much more. Once an organization has correctly assessed and identified workplace specific confined spaces, all critical stakeholders (entry supervisors, entry attendants, entrants, rescue personal, etc) must receive adequate certification training aimed at assuring competency in job specific execution. Regulation 632-05, The Act and CSA Z1006 act as a template of expectation for assessment, program development and training benchmarks. Participants will learn about relevant terms, definitions, current regulations/standards, characteristics of a confined space and assessment techniques, stakeholder duties, entry and hot work permits, air monitoring, PPE, ventilation and purging techniques, LOTO, non-entry rescue, and so much more.

Once an organization has correctly assessed and identified workplace specific confined spaces, all critical stakeholders (entry supervisors, entry attendants, entrants, rescue personal, etc) must receive adequate certification training aimed at assuring competency in job specific execution. Regulation 632-05, The Act and CSA Z1006 act as a template of expectation for assessment, program development and training benchmarks. Participants will learn about relevant terms, definitions, current regulations/standards, characteristics of a confined space and assessment techniques, stakeholder duties, entry and hot work permits, air monitoring, PPE, ventilation and purging techniques, LOTO, non-entry rescue, and so much more. Workplace fire prevention is critical to the protection of Life, Environment and Property. Unfortunately, despite the best preventative measures and preparedness, fire-based emergencies can still be a hard reality within any workplace. It is estimated that only 1 in every 10 workers are familiar with and would know how to use an available fire extinguisher in that moment. Let New World Safety assist your employees with this life critical skill set. Participants will learn about key terms and definitions, classes of fire, extinguisher classifications and characteristics, how fire spreads, basic workplace fire prevention techniques, PASS acronym and how to use extinguishers correctly, limitations of extinguishers and when it is time to back away, extensive and practical hands-on.

Workplace fire prevention is critical to the protection of Life, Environment and Property. Unfortunately, despite the best preventative measures and preparedness, fire-based emergencies can still be a hard reality within any workplace. It is estimated that only 1 in every 10 workers are familiar with and would know how to use an available fire extinguisher in that moment. Let New World Safety assist your employees with this life critical skill set. Participants will learn about key terms and definitions, classes of fire, extinguisher classifications and characteristics, how fire spreads, basic workplace fire prevention techniques, PASS acronym and how to use extinguishers correctly, limitations of extinguishers and when it is time to back away, extensive and practical hands-on. Flammable and Combustible liquids are notorious for their ability to accumulate a static charge and significantly enhance the risk of fire/explosion, when improperly stored, handled or used. Proper grounding and bonding techniques are critical to eliminating that hazard and risks. Even organizations using grounding and bonding on a regular basis, fail to inspect and maintain all equipment to assure functionality. Participants will learn about relevant terms and definitions, the theory of fire and static electricity, the dos and don’ts with grounding and bonding, good grounds versus bad grounds, anti-static measures, grounding and bonding cables and clamps, continuity testing, and so much more.

Flammable and Combustible liquids are notorious for their ability to accumulate a static charge and significantly enhance the risk of fire/explosion, when improperly stored, handled or used. Proper grounding and bonding techniques are critical to eliminating that hazard and risks. Even organizations using grounding and bonding on a regular basis, fail to inspect and maintain all equipment to assure functionality. Participants will learn about relevant terms and definitions, the theory of fire and static electricity, the dos and don’ts with grounding and bonding, good grounds versus bad grounds, anti-static measures, grounding and bonding cables and clamps, continuity testing, and so much more. NFPA 472/1072 stands as the international training standard for emergency response teams the world over. Every organization must conduct a comprehensive chemical hazard assessment to determine which dangerous goods pose a risk to Life, Environment and Property. Once chemical risks have been identified the employer must consider how to prevent, prepare for, respond to and remediate from any potential hazardous materials release. When it comes to a decision of the level of training required, NFPA offers options based on the chemical risks and volumes onsite, the availability of certified and competent municipal hazmat response within your community (remember few small communities have the budget to support this), the capability that your organization has to support the development of your own sustainable team, and your budget. Let NewWorldSafety assist you on this journey with sound recommendations and assessment techniques. Participants will learn topics that will become more robust based on the level of NFPA certification selected. Generally speaking participants will learn about key terms and definitions, relevant standards and legislation, the IMS system and team structure, chemical classifications and characteristics, hazard symbols and meaning, information resources, creating hazard control zones, setting up for an entry, predicting the behavior of spilled materials, PPE, chemistry and toxicology (street smart), information resources, the critical importance of air monitoring, decontamination techniques (entrants, tools, victims), planning a response (offensive versus defensive actions), containment, confinement, cleanup operations, and so much more.

NFPA 472/1072 stands as the international training standard for emergency response teams the world over. Every organization must conduct a comprehensive chemical hazard assessment to determine which dangerous goods pose a risk to Life, Environment and Property. Once chemical risks have been identified the employer must consider how to prevent, prepare for, respond to and remediate from any potential hazardous materials release. When it comes to a decision of the level of training required, NFPA offers options based on the chemical risks and volumes onsite, the availability of certified and competent municipal hazmat response within your community (remember few small communities have the budget to support this), the capability that your organization has to support the development of your own sustainable team, and your budget. Let NewWorldSafety assist you on this journey with sound recommendations and assessment techniques. Participants will learn topics that will become more robust based on the level of NFPA certification selected. Generally speaking participants will learn about key terms and definitions, relevant standards and legislation, the IMS system and team structure, chemical classifications and characteristics, hazard symbols and meaning, information resources, creating hazard control zones, setting up for an entry, predicting the behavior of spilled materials, PPE, chemistry and toxicology (street smart), information resources, the critical importance of air monitoring, decontamination techniques (entrants, tools, victims), planning a response (offensive versus defensive actions), containment, confinement, cleanup operations, and so much more. Certain workplace activities significantly increase the risk of a fire or explosion emergency. Hot Work practices are defined as any temporary operation involving open flames or producing heat and/or sparks conducted outside a Hot Work Designated Area. This includes, but is not limited to brazing, cutting, grinding, soldering, torch-applied roofing and welding. Prior to engaging in these types of activities it is critical to ensure a workplace specific Hot Work program/permit is implemented and followed without waiver. Too many workplaces pay lip service to the attributes for dedicated fire watch personnel. Let NewWorldSafety levy 34 years of experience in this area to your program. Participants will learn about key terms and definitions, how to properly conduct a compliant assessment of a Hot Work area prior to execution, how to use, properly complete and retain your corporate Hot Work permit, stakeholder duties (hot work supervisor, hot work personnel, fire watch), preparing the site for Hot Work (fire blankets, blanking, purging, air monitoring and more), types of extinguishers and usage, and so much more.

Certain workplace activities significantly increase the risk of a fire or explosion emergency. Hot Work practices are defined as any temporary operation involving open flames or producing heat and/or sparks conducted outside a Hot Work Designated Area. This includes, but is not limited to brazing, cutting, grinding, soldering, torch-applied roofing and welding. Prior to engaging in these types of activities it is critical to ensure a workplace specific Hot Work program/permit is implemented and followed without waiver. Too many workplaces pay lip service to the attributes for dedicated fire watch personnel. Let NewWorldSafety levy 34 years of experience in this area to your program. Participants will learn about key terms and definitions, how to properly conduct a compliant assessment of a Hot Work area prior to execution, how to use, properly complete and retain your corporate Hot Work permit, stakeholder duties (hot work supervisor, hot work personnel, fire watch), preparing the site for Hot Work (fire blankets, blanking, purging, air monitoring and more), types of extinguishers and usage, and so much more. Energy is an absolute necessity to our modern manufacturing world. But for all the modern convenience afforded by the robust array of energy around us, each form of energy brings forth its own set of hazards and risks. CSAZ460 defines hazardous energy as: any electrical, mechanical, hydraulic, pneumatic, chemical, nuclear, thermal, gravitational, or other energy that can harm personnel. When it comes to assigning activities to your authorized employees do not pay lip service to ensuring they set the stage correctly, with proper energy control. Participants will learn about relevant terms and definitions, types of energy with associated hazards and risks, the importance of guarding as a method of control, developing LOTO placards and proper identification of energy isolation devices, the seven steps to effective energy control, LOTO devices and how to apply them, PPE, group LOTO, authorized versus affected employees, contractors and LOTO, abandoned LOTO devices and lock removal, continuity in LOTO between shifts, and so much more!

Energy is an absolute necessity to our modern manufacturing world. But for all the modern convenience afforded by the robust array of energy around us, each form of energy brings forth its own set of hazards and risks. CSAZ460 defines hazardous energy as: any electrical, mechanical, hydraulic, pneumatic, chemical, nuclear, thermal, gravitational, or other energy that can harm personnel. When it comes to assigning activities to your authorized employees do not pay lip service to ensuring they set the stage correctly, with proper energy control. Participants will learn about relevant terms and definitions, types of energy with associated hazards and risks, the importance of guarding as a method of control, developing LOTO placards and proper identification of energy isolation devices, the seven steps to effective energy control, LOTO devices and how to apply them, PPE, group LOTO, authorized versus affected employees, contractors and LOTO, abandoned LOTO devices and lock removal, continuity in LOTO between shifts, and so much more! The proper selection, use and care of respiratory protection has always been a high priority within any sector specific workplace. But no time in history has placed a higher priority or realization towards this topic, than the pandemic with it’s multiple waves of infection. Whether it be an N95 mask, half or full-face APR (air purifying respirator), PAPR (powered air purifying respirator, SAR (supplied air breathing system) or and SCBA (self- contained breathing apparatus) your workers must be medically cleared, properly fitted, properly fit tested and trained prior to any first usage for any of the above noted types of respirators. Participants will learn about relevant terms and definitions, workplace hazard/risk assessment, types of respiratory protection, medical evaluation techniques, respiratory fit testing techniques, facial hair issues and recommendations, proper donning and doffing techniques for your workplace specific makes/models, proper storage, cleaning, and disinfection of workplace respirators, cartridge change intervals (ELSI), emergency bypass issues with SCBA, and so much more. Note: respiratory fit testing using quantitative techniques (porta count 8038) available upon request.

The proper selection, use and care of respiratory protection has always been a high priority within any sector specific workplace. But no time in history has placed a higher priority or realization towards this topic, than the pandemic with it’s multiple waves of infection. Whether it be an N95 mask, half or full-face APR (air purifying respirator), PAPR (powered air purifying respirator, SAR (supplied air breathing system) or and SCBA (self- contained breathing apparatus) your workers must be medically cleared, properly fitted, properly fit tested and trained prior to any first usage for any of the above noted types of respirators. Participants will learn about relevant terms and definitions, workplace hazard/risk assessment, types of respiratory protection, medical evaluation techniques, respiratory fit testing techniques, facial hair issues and recommendations, proper donning and doffing techniques for your workplace specific makes/models, proper storage, cleaning, and disinfection of workplace respirators, cartridge change intervals (ELSI), emergency bypass issues with SCBA, and so much more. Note: respiratory fit testing using quantitative techniques (porta count 8038) available upon request. Whether you be a shipper/consigner, a carrier, the operator of a workplace lift truck, a supervisor or handler of any dangerous goods TDG training has you in its cross hairs. Employers must always ensure those trusted with the duty of handling, transporting or shipping any of the nine classes of dangerous goods either possesses a current TDG certification, or are directly supervised by an employee who does in that moment. Conversely any employee trusted with reviewing and signing a waste manifest must hold a current/valid TDG certification. Participants will learn about relevant terms and definitions, The TDG Act, Part 1 Special Cases for exemption, Part 2 chemical classification for the nine classes of dangerous goods, Part 3 Documentation, Part 4 labels and placards, Part 5 means of containment, Part 6 Training, Part 7 ERAPs, Part 8 Imminent reporting for accidental releases or lost/stolen dangerous goods, parts 9-16, Schedules 1-3, a bit about regulation 347 and waste manifests, and so much more.

Whether you be a shipper/consigner, a carrier, the operator of a workplace lift truck, a supervisor or handler of any dangerous goods TDG training has you in its cross hairs. Employers must always ensure those trusted with the duty of handling, transporting or shipping any of the nine classes of dangerous goods either possesses a current TDG certification, or are directly supervised by an employee who does in that moment. Conversely any employee trusted with reviewing and signing a waste manifest must hold a current/valid TDG certification. Participants will learn about relevant terms and definitions, The TDG Act, Part 1 Special Cases for exemption, Part 2 chemical classification for the nine classes of dangerous goods, Part 3 Documentation, Part 4 labels and placards, Part 5 means of containment, Part 6 Training, Part 7 ERAPs, Part 8 Imminent reporting for accidental releases or lost/stolen dangerous goods, parts 9-16, Schedules 1-3, a bit about regulation 347 and waste manifests, and so much more.